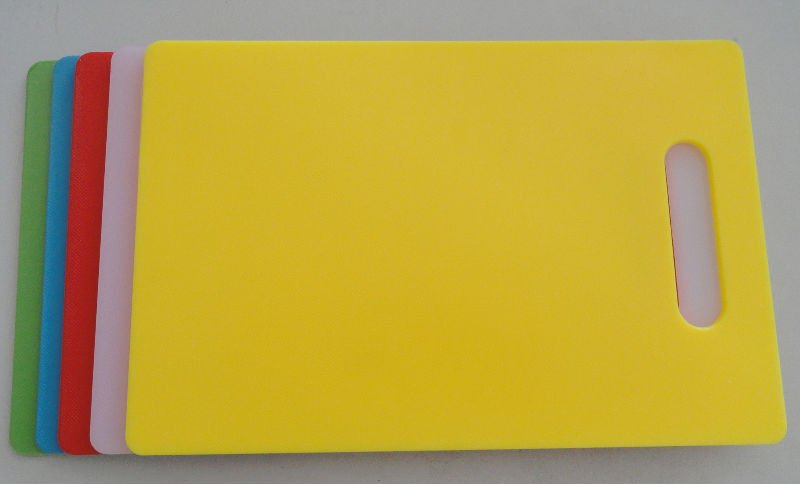

HDPE as a cutting surface

Next time you find yourself chopping green veggies on your own chopping board, spend some time and look at it, the material most likely to be used as a HDPE Polyethylene Cut Grade Material - Sheets cutting board is Polyethylene. Given that it can be FDA and NSF approved in addition to stain, moisture and odor resistant, Polyethylene is an ideal choice for chopping boards.

A variety of other cutting boards cut from wood are prone to bacteria and odors because they lack the desiredproperties that Polyethylene sheets offer, for instance its non permeable surface, chemical resistance and approval for food contact. High Density Polyethylene is an extremely durable and lighter weight material that comes in many forms and is great for a wide variety of applications. You can find several varieties of Polyethylene commercially available. The most typical are HDPE (High Density Polyethylene), Low Density Polyethylene, and UHMW (Ultra High Molecular Weight Polyethylene). The the main difference has to do with the molecular weight and branching; which happens when a monomer or atom is replaced by a longer chain of polymers (a very long repeating chain of atoms).

{ |

||

|

The High Density is commonly used for milk jugs and glad food storage containers. Low Density is typically used for milky colored bottles as well as plastic grocery bags. UHMW, which has higher molecular weight (2-6 million) that allows for an even transfer over the length of material which makes it stronger, which makes it able to be used for bearing purposes due to its great wear resistance. Commonly utilized in the food processing and dairy industry, Ultra High Molecular Weight Polyethylene is an effective replacement for various industrial materials and a fantastic solution to many wear issues. These types of polymers are derived from the same polyolefin plastic materials family, but they all have certain properties that make them a little different. HDPE provides great chemical resistance, has exceptional impact strength and great energy absorption. LDPE has several of the same properties as High Density but it's not as dense at 9.15, instead of HDPE which is 9.34, and is also a softer material ( the one gallon coffee can lids). Aside from that it features a lower tensile strength along with better, simpler and easier formability.

UHMW is a strong material with which has great durability and low co-efficient of friction rendering it an ideal for sliding applications. Dupont makes the plastic material with a lower co-efficient of friction is Teflon - PTFE; which has a higher temperature and chemical resistance. UHMW Polyethylene is equipped with a great deal of material offerings and properties, and all these materials include extraordinary durability that may be best with numerous applications. From the food industry to automotive, your kitchen and even the warehouse, whatever your Polyethylene needs are - High Density, Low Denseness or perhaps UHMW, Polyethylene is a superb option. Send email for more information on these or any other plastic sheet or rod materials.

Comments

Post a Comment